How to Increase The Batch Size Of A Bread Recipe

After mastering a handful of bread recipes, learning how to increase the batch size of a recipe is a natural step. Batch baking allows you to make more loaves of bread using a similar amount of effort, saving you time and money.

Some bakers get confused, especially when wondering if they should double the yeast if the recipe is doubled, so I’ve written this article to help you clear a few things up.

How to increase the batch size of a bread recipe

Ultimately, there are two cases where increasing the size of a dough recipe is necessary:

- Using a different sized baking tin (or basket) for the recipe

- Making more or fewer loaves of the same recipe

Some dough recipes are suited to make different varieties of bread. With the same white bread dough used in bloomers, farmhouse loaves, sandwich bread, Pullman bread, crusty rolls, iced buns, and sometimes baguettes!

Increasing the batch size saves time used to weigh and mix the ingredients. It does have its drawbacks, in that all the bread tastes the same! After mixing, you can change how you manipulate each bread type to make each unique.

We might also need to make less dough by decreasing the batch size of the dough. For this, the same technique is used. Let me show you how it works.

Bakers formula

To determine how much we need of each ingredient when you want to make twice as much, you just double the recipe, easy. But when it comes to other calculations, it becomes harder to do the maths accurately.

Adjusting the quantities required for each ingredient is essential to achieve consistency in our bread every time.

Spending a bit of time to properly adjust the weight of each ingredient will save you time faffing around later on trying to save an uneven mix!

We use a baker’s formula to calculate what each ingredient should be as we scale up or down a bread recipe. This is essentially the formula of the recipe given in percentages from which the recipe is created.

Some professional bread recipes provide the baker’s percentage figures, but if not, they are pretty simple to work out.

Here’s how it works:

Let’s use an example where the recipe has a batch size of one loaf, and we will change it to make three loaves of bread. Here’s the recipe in its current form:

480g white flour 50g wholemeal flour 350g water 11g salt 12g yeast Total dough weight = 903g

Add all the flour used in the recipe. There’s no adding up required for recipes using just one type of flour. For those with more than two flour types, add them together for the total.

480g white flour 50g wholemeal flour 480 + 50 = 530 Total flour weight 530g

Once the total flour weight is determined as 100% we use the total flour weight to base the quantities of the remaining ingredients from.

To calculate the percentages of the remaining ingredients, we take their weight, divide it by the total weight of flour, and multiply by 100 to get a percentage.

Here’s how we calculate the water percentage:

530g of total flour is 100% 350g = water 350/530 = 0.66 0,66 * 100 = 66%

And then using the same method of:

(weight of ingredient / weight of total flour) x 100 = Baker's percentage

We work out the baker’s percentage for all the remaining ingredients, not forgetting we have two types of flour, so these will also have to be calculated separately.

White flour = 91% Wholemeal flour = 9% (the total flour will always add up to 100%) Water = 66% Salt = 2.1% Yeast = 2.3%

We have now calculated the baker’s percentages for all the ingredients and produced our baker’s formula for the recipe.

How to change the size of the recipe

To increase or decrease the amount of dough we want, first, we need to find the new total flour weight. As we are tripling the recipe, we will multiply the original total flour weight be 3.

530 * 3 = 1590Using the total flour weight, we use the following formula:

( Total flour weight / 100 ) x ingredient percentage = ingredient weight

And calculate the new weight of each ingredient:

White flour @ 91%

1590 / 100 * 91 = 1447g

Wholemeal flour @ 9% 1590 / 100 * 9 = 143g

Water @ 66% 1590 / 100 * 66 = 1049g

Salt = 2.1% 1590 / 100 * 2.1 = 33.4g

Yeast = 2.3% 1590 / 100 * 2.3 = 36.6g

Total dough weight = 2709gWe now have our new recipe with the same ratio of ingredients as the original. It’s up to you if you wish to round up the figures to “rounder numbers,” which will lose accuracy but make the recipe more friendly to read and follow:

1447g white flour 143g wholemeal flour 1049g water 33.4g salt 36.6g yeast

We can create a spreadsheet to quickly work out these calculations similar to this baker’s formula. Suppose you have a reasonable knowledge of using spreadsheets such as Excel or Google Sheets. In that case, it is straightforward to set up.

Here’s a baker’s formula for my basic white bread.

As I scaled my business, I used a similar spreadsheet that added up daily orders and told me how much dough I needed for each recipe.

I would need to tailor the flour weight on each recipe to match the required amount of dough, and my recipes would be ready to go. This technique meant I could calculate my entire night’s production in 5 minutes with minimal waste.

Tips for increasing the size of the recipe

We’ve covered how to change the batch size of the dough, but now we will go over a few questions that often get asked when increasing the size of the recipe and a few common issues bakers discover when using bigger doughs.

When to divide dough into individual pieces?

When making more than one bread from a batch of dough, you will divide the dough into individual pieces to form your individual bread. Dividing should occur after bulk fermentation so that the dough structure is developed sufficiently to retain gas and rise. It also saves on space, and dough gains the benefits of the mass effect (I’ll explain in a moment).

In certain circumstances, you can divide the dough before bulk fermentation ends. These situations include separating a master dough for adding additional ingredients or making different bread shapes that want separate proofing/fermentation conditions.

Increasing the recipe to bake more bread the next day

Making a larger batch size to enjoy fresh bread the following day is a handy trick that will save you time and energy in making another batch. Even a small amount of dough can be used for a pizza or flatbread to accompany a meal.

For best results, cool the dough in the fridge to slow the fermentation rate. This reduces the chance of the dough becoming overripe the following day.

Depending on the amount of levain activity (yeast or sourdough are common levains), the amount of time the dough is in the fridge will determine when the dough portion should be separated.

For doughs with high amounts of yeast or high amounts of a very active levain, the dough is placed in the fridge straight after mixing.

For most sourdough or artisan bread made with small quantities of yeast, this is not the case. The dough undergo bulk fermentation at ambient temperature overnight. The following morning the dough is divided, shaped, and left in the fridge for a final overnight proof.

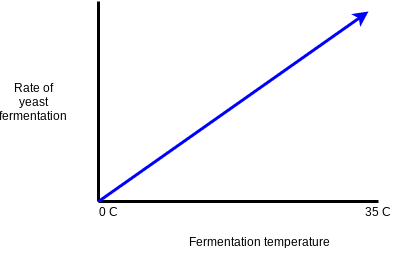

The mass effect in bread dough

Flour contains many different particles, varying from plant to plant and even grain to grain.

Flour quality is affected by different amounts of sunlight, water, the soil, or as the French say, the “Terroir.”

In dough, yeast and flour enzymes break down the starch. This leads to yeast respiration and later fermentation, where carbon dioxide, ethanol, and lactic and organic acids are produced.

Bigger batches of dough contain more flour. A big batch of dough contains a wider variety of minerals and bacteria, which help the yeast and the enzymes to work faster.

The increase in the rate of fermentation and the varieties of developed enzymes create a dough with superior flavour and maturity.

This is the power of the “Mass Effect”.

When increasing the batch size of the recipe, we find fermentation rates increase. Therefore, we can reduce the time of the fermentation required or lower the quantity of the levain to compensate.

Should the yeast be doubled if I double the recipe?

When doubling a recipe, the yeast can be reduced slightly. By not doubling the yeast alongside the rest of the ingredients, you are, in effect, halving the quantity of yeast. This is far too much of a reduction.

A 10% reduction when doubling the recipe is sufficient. However, this amount is usually so negligible it’s not worth bothering about. Especially when you consider the other variables, such as temperature and the freshness of the yeast.

Where the total dough size is under 1500 grams, the amount of yeast is not usually reduced as the mass effect has little impact on small dough sizes.

When doubling a recipe, it is better to reduce the first and second rise durations. This is why it’s better to learn what dough should look when you are ready to end bulk fermentation than simply watching the clock.

Do I change the mixing times for larger or smaller amounts of dough?

As batch sizes increase, the dough will require more effort from the mixer to knead. Professional dough mixers knead dough without resistance. They are powerful enough not to slow down as they knead stiff or large amounts of dough.

Less powerful stand mixers often find it harder to knead more significant amounts of dough so, the mixing times may have to be increased. A 10-20% increase in the mixing time is usually all that is required.

Why do I have trouble kneading in a mixer when I change the size of my dough batch?

Mixers have an ideal dough weight that they are most comfortable mixing.

Some dough mixers struggle to make small amounts of dough but work fantastic when they approach capacity.

Other mixers can slow down or struggle with large batches, especially when the dough has a low water ratio.

If you are looking to make bread dough quickly you’ll probably be intensively kneading your dough and proofing in warm temperatures. This might not be possible without a quality dough mixer and a warm room (or proofing box). These are the limitations of the equipment, so without trading up our stand mixers, it is best to learn how the mixer reacts when the dough weight changes and adjust our batch sizes accordingly.

If you’ve enjoyed this article and wish to treat me to a coffee, you can by following the link below – Thanks x

Hi, I’m Gareth Busby, a baking coach, senior baker and bread-baking fanatic! My aim is to use science, techniques and 15 years of baking experience to make you a better baker.

Table of Contents

- How to increase the batch size of a bread recipe

- Bakers formula

- How to change the size of the recipe

- Tips for increasing the size of the recipe

- When to divide dough into individual pieces?

- Increasing the recipe to bake more bread the next day

- The mass effect in bread dough

- Should the yeast be doubled if I double the recipe?

- Do I change the mixing times for larger or smaller amounts of dough?

- Why do I have trouble kneading in a mixer when I change the size of my dough batch?

Related Recipes

Related Articles

Latest Articles

Baking Categories

Disclaimer

Address

53 Greystone Avenue

Worthing

West Sussex

BN13 1LR

UK